Automotive ceiling handle

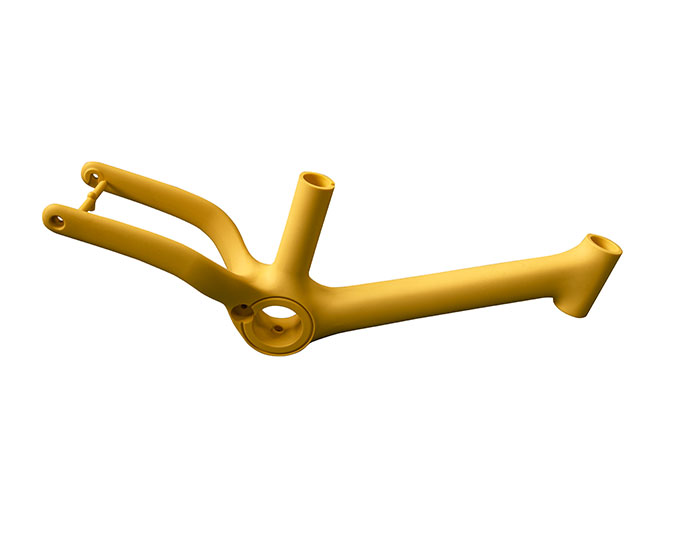

Gas-assisted injection molding of kettle handlesWhat is the gas-assisted injection molding? Today we will talk about the case of gas-assisted injection molding of kettle handles. During the injection molding process, push the melt plastic to fi...More+

Gas-assisted injection molding of kettle handlesWhat is the gas-assisted injection molding? Today we will talk about the case of gas-assisted injection molding of kettle handles. During the injection molding process, push the melt plastic to fi...More+

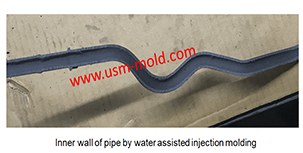

Comparison of water-assisted and gas-assisted injection moldingComparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid an...More+

Comparison of water-assisted and gas-assisted injection moldingComparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid an...More+

Gas & Water Assisted Injection MoldThe differences between water-assisted and gas-assisted molding1. Water-assisted injection molding uses water, and it can be recycled and reused, so the medium water of the two molding processes is cheaper than nitrogen.More+

Gas & Water Assisted Injection MoldThe differences between water-assisted and gas-assisted molding1. Water-assisted injection molding uses water, and it can be recycled and reused, so the medium water of the two molding processes is cheaper than nitrogen.More+

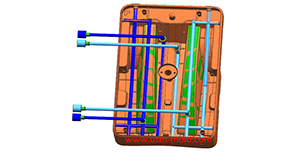

The principle of mold temperature balance in plastic mold cooling system designThe principle of mold temperature balance:1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be mak...More+

The principle of mold temperature balance in plastic mold cooling system designThe principle of mold temperature balance:1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be mak...More+

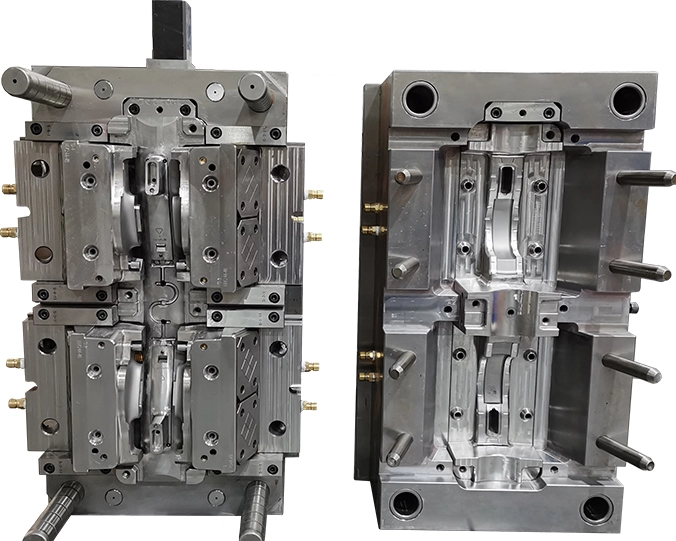

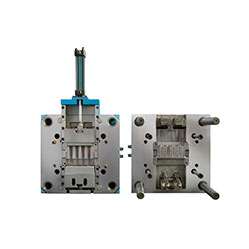

Company ProfileUSM is one of the world's leading manufacturers of the plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K...More+

Company ProfileUSM is one of the world's leading manufacturers of the plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K...More+

Medical TPE MoldSince the establishment of the factory, USM has provided injection molding products and injection mold services for many medical companies around the world, especially in medical multi-cavity and small products (pipetting tips) with rich and valuable experience.More+

Medical TPE MoldSince the establishment of the factory, USM has provided injection molding products and injection mold services for many medical companies around the world, especially in medical multi-cavity and small products (pipetting tips) with rich and valuable experience.More+

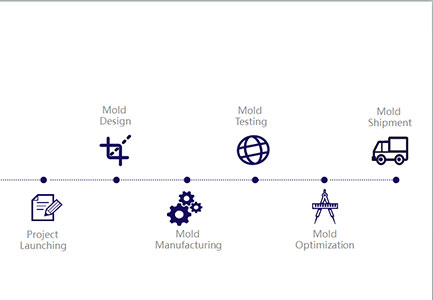

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

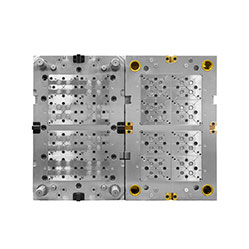

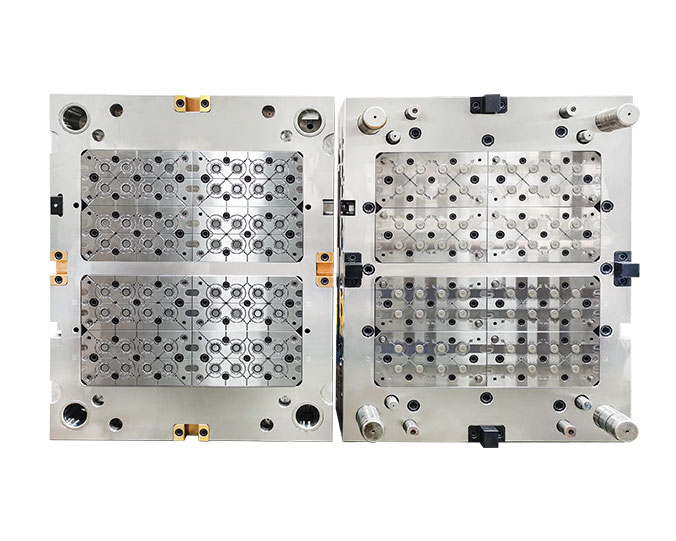

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

English

English русский

русский