gas assisted injection mold

Quality ControlQuality is the soul of USM at all times, the procedure of quality control, quality insurance, and quality monitoring are integrated into every operation step, and all operations are guaranteed with ISO 90001.More+

Quality ControlQuality is the soul of USM at all times, the procedure of quality control, quality insurance, and quality monitoring are integrated into every operation step, and all operations are guaranteed with ISO 90001.More+

2022 Shenzhen Industrial Exhibition ITES ended successfullyThe 2022 ITES Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition and the 23rd Shenzhen International Machinery Manufacturing Exhibition were grandly opened in Shenzhen...More+

2022 Shenzhen Industrial Exhibition ITES ended successfullyThe 2022 ITES Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition and the 23rd Shenzhen International Machinery Manufacturing Exhibition were grandly opened in Shenzhen...More+

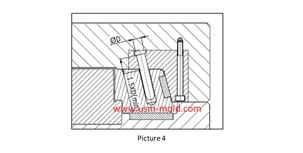

The common fixing method of angle pinThe angle pin is a common part of the drive slider, and the fixing and installation methods as following:1. Pass through the mold plate directly and press the angle pin with the top plate to fix it, a...More+

The common fixing method of angle pinThe angle pin is a common part of the drive slider, and the fixing and installation methods as following:1. Pass through the mold plate directly and press the angle pin with the top plate to fix it, a...More+

Company ProfileUSM is one of the world's leading manufacturers of the plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K...More+

Company ProfileUSM is one of the world's leading manufacturers of the plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K...More+

_20250317101516A021.jpg) The basic points of designing gas-assisted injection molding1. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel;2. The gas channel should be arranged in balan...More+

The basic points of designing gas-assisted injection molding1. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel;2. The gas channel should be arranged in balan...More+

Mold AssemblingTo assemble the mold but not without fitting is the goal for every bench worker, and it has become the soul of every USM employee.More+

Mold AssemblingTo assemble the mold but not without fitting is the goal for every bench worker, and it has become the soul of every USM employee.More+

Medical Plastic MoldProduct material: PP material in medical-gradeMold steel: S136 HRC 52-54Mold life: 1 millionHot runner brand: IncoeMold base: LKMSurface finishing: Mirror polishingMold lead time: 6 weeksMore+

Medical Plastic MoldProduct material: PP material in medical-gradeMold steel: S136 HRC 52-54Mold life: 1 millionHot runner brand: IncoeMold base: LKMSurface finishing: Mirror polishingMold lead time: 6 weeksMore+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

English

English русский

русский