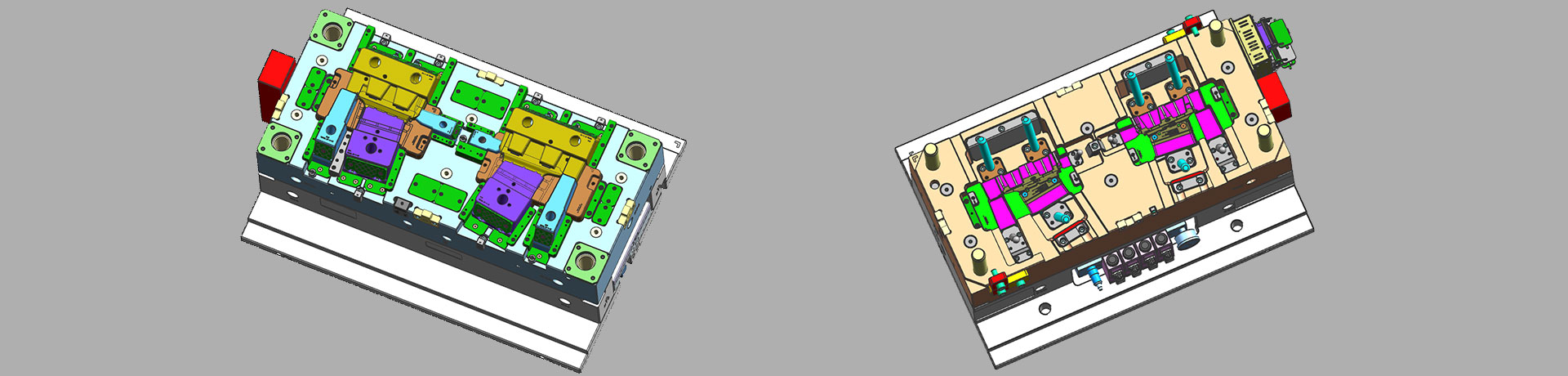

Plastic injection mold cooling system design notice

Design notice of designing the cooling system:

1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer;

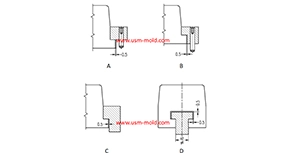

2. Using less sealing ring when design the cooling gate system, and the water pipe is better to be two-way straight, which is convenient for repairing when it is blocked. Note that the seals and faucet pipes are prone to water leakage and water seepage, and the dimensional tolerances of the sealing grooves should meet the requirements;

3. When using PE or other materials, because of the big molding shrinkage, the cooling gate should be arranged along the shrinking direction to make the plastic parts not easy to deform. The water channels are arranged longitudinally according to the arrangement direction of the cavity and core;

4. When the mold has only one water inlet and one water outlet, the cooling pipes should be connected in series, if parallel connection is used, the flow resistance of each circuit is different, and it is difficult to form the same cooling conditions. When parallel connection is required, a water volume adjustment device, flow meter and flow meter should be installed in each loop;

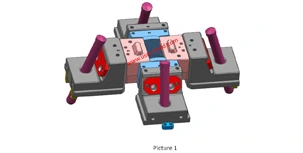

5. If the cooling effect is not good and the structure is restricted by the shape of the structure, in order to improve the cooling effect, consider choosing a material or structure with good thermal conductivity, such as beryllium copper, copper alloy, or a thermal conductive rod structure. The cavity, the core, inserts, and sliders must be cooled by every means if neccessary;

.jpg)

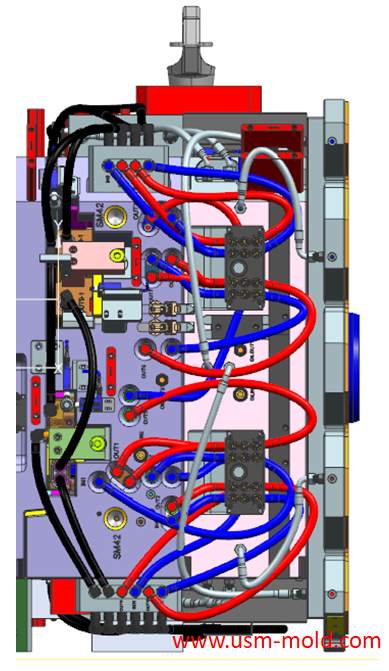

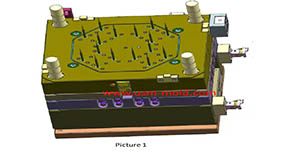

6. The inlet pipe joint area is marked with red, and the outlet pipe joint is marked with blue;

7. In the position near the cooling water inlet and outlet of the cavity with core side, mark the entry "IN" and the exit "OUT" in English; and mark the water gate accordingly.

USM Blogo Opening

Oct 27, 2021Hello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need. USM is a professional plastic injection mold and molding...view

Slider designing tips 2

Nov 22, 20239. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view_20250317091228A019.jpg)

Main application of gas-assisted molding technology

Apr 7, 2022Gas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the...view

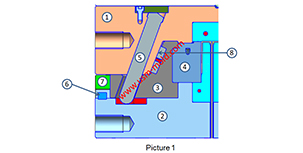

Slider of side core pulling mechanisum assembling

Jul 21, 2022The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...view

English

English русский

русский