Several common process of water-assisted injection molding introduction

According to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the backflow method and the overflow method, and according to the part shape and size, the water-assisted injection molding process is divided into two types: water push injection molding and projectile injection molding, each of these two processes has its own characteristics and application scenarios, according to the part shape and equipment function, when the water returns back, it is also divided into two methods: gravity return and vacuum dewatering.

Backflow method:

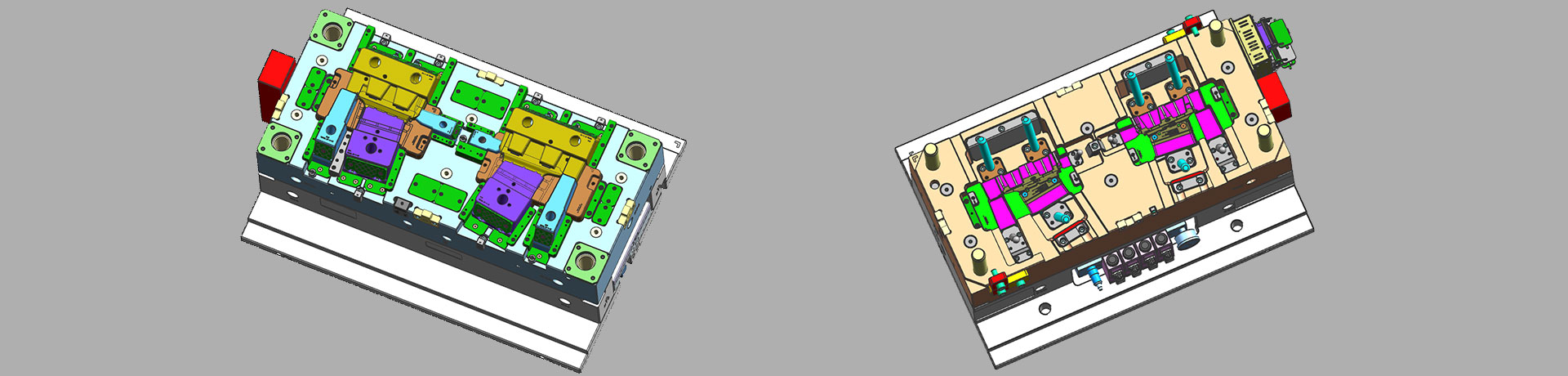

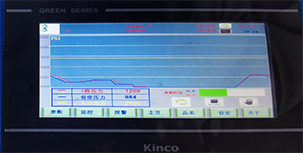

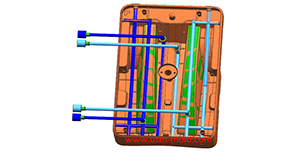

The backflow method (melt reflow method or reverse push method) is to fill the mold cavity with the melt first during injection molding, and the water assisted injection moulding equipment uses water pressure to push the unsolidified melt in the middle of the product through the hot runner and then return to the injection molding machine barrel, the retreated melt will be reused when the next mold is injected. However, this process has more complicated requirements for the structure of the mold, and the cost is much higher, this process must use a needle valve hot runner, a pressure sensor is also needed on the mold, and an additional sensor is added to the nozzle of the water injection moulding machine.

.png)

Overflow method:

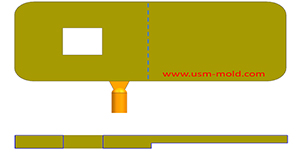

The water-assisted overflow method is the same as the gas-assisted overflow method, this process requires an additional cavity on the mold, the volume of this cavity is equal to or slightly larger than the volume of the product hollowed out, this cavity is closed by the valve needle before filling plastic, the valve needle of water-assited equipemnt starting spray water and the mold cavity is filled with melt plastic, the valve needle is controlled by the hydraulic cylinder to open at the same time, and the melt pushed by the water will return to this cavity, compared with the backflow method, this process is much cheaper, and the injection molding machine does not require special modification, but the material waste too much.

Water push injection molding process:

The water push injection molding process means that water is directly sprayed from the water needle during water-assisted injection molding to push the melt back without additional auxiliary parts, compared with the projectile method, this process may shorten the molding cycle and save mold costs, because it can save mold cost of bullet, but the shortcomings is also obvious, the water push process cannot produce products with large diameters, small changes in the injection molding process will have a significant impact on the size of the inner hole of the product, if the injection molding process is not mastered, the water will easily run into the heat flow. If the opening time of the water needle is not controlled well, the plastic will easily run into the water needle and block the water nozzle.

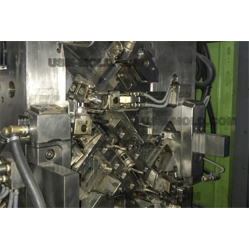

Projectile method:

The bullet ejection method is to add a plastic part like a bullet in front of the water needle, the temperature resistance of this part must be the same asinjection molding material, when the water needle starts to spray water, the water will push the bullet forward first, the buller pushes the melt back again, after adjusting the outer diameter of the bullet, the inner hole size of the product will also change, this method requires relatively simple injection molding process, even if the opening time of the water needle is not controlled, the plastic will not tunning into the water nozzle which will cause damage to the water nozzle, due to the limitation of the bullet front side, the water will not be easily injected into the hot runner and injection molding machine. However, this process requires a bullet to be placed on the water nozzle after the mold is opened, and the molding cycle is longer than that of the water push method. an additional set of bullet molds is required too.

Side gate of plastic injection mold runner system design

Jan 23, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Gate position determination of plastic injection mold runner design system

Jan 17, 2022In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...view

Key points of gas-assisted injection molding process

Apr 20, 2022Gas injection parameters The gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas...view

The principle of mold temperature balance in plastic mold cooling system design

Feb 21, 2022The principle of mold temperature balance: 1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be...view

Gas-assisted Injection Molding Equipment

Apr 10, 2022The gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection...view

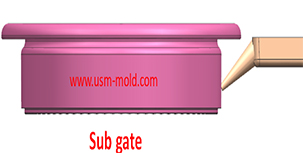

The sub gate of the plastic injection mold runner system

Jan 26, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

English

English русский

русский