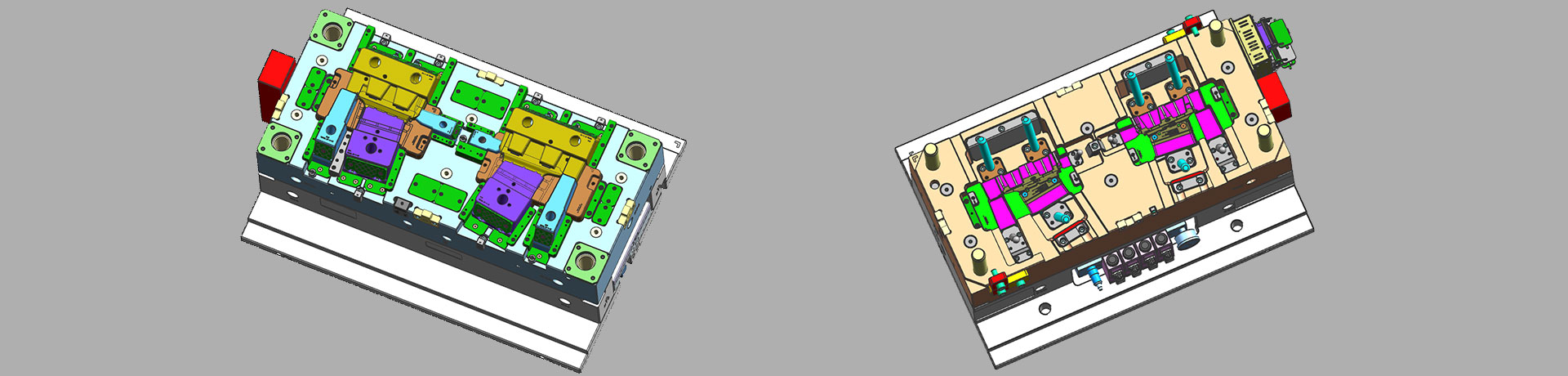

Classification of side parting and core pulling mechanism

According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories:

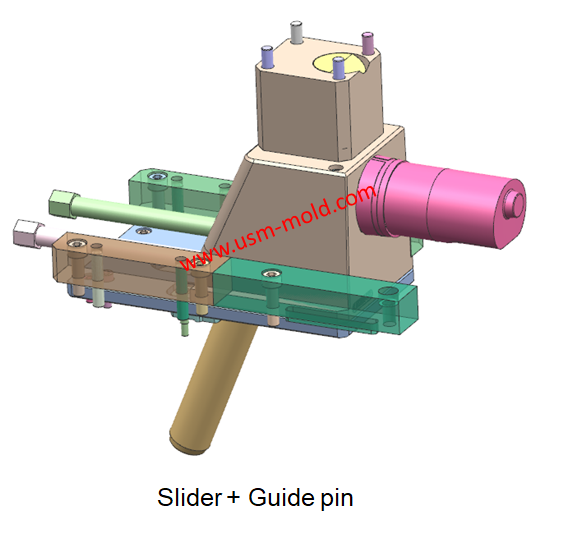

1. The side core-pulling mechanism of "slider + guide pin";

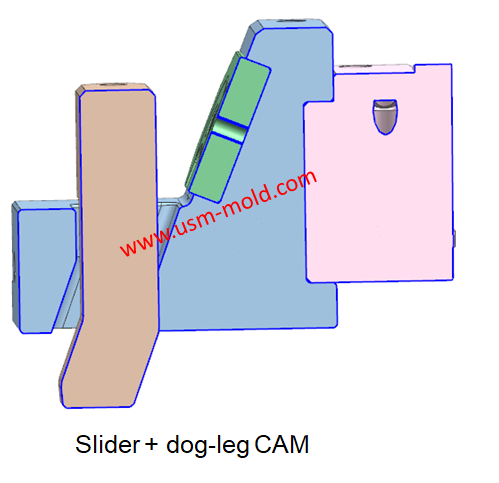

2. The side core-pulling mechanism of "slider +dog-leg CAM";

3. The side core-pulling mechanism of "slider + T-block";

4. The side core-pulling mechanism of slider + hydraulic cylinder;

5. Side core pulling mechanism of lifter;

6. side core pulling mechanism of side slider.

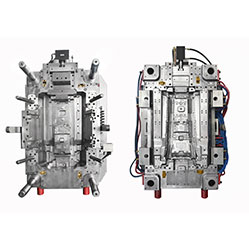

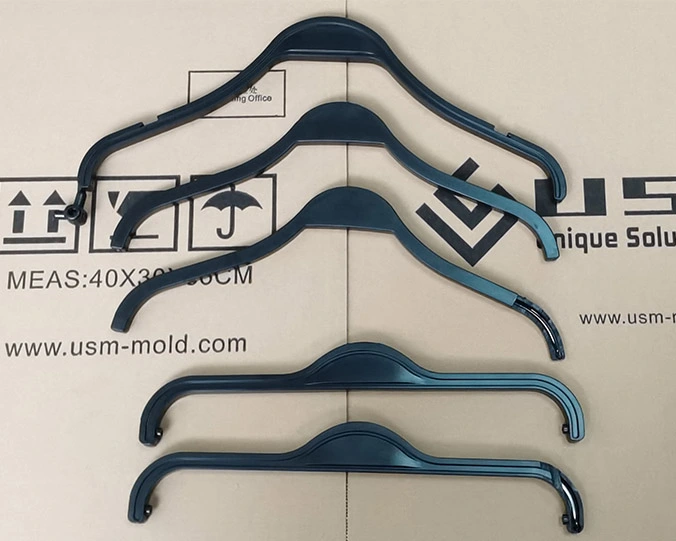

Popular USM Injection Molds

Related News about USM Injection Mold

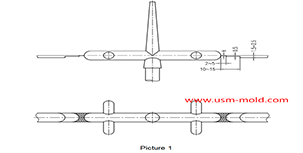

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view

Slider angle designing tips

Dec 4, 20231. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...view

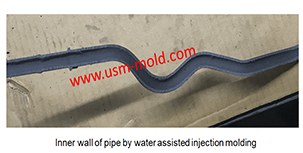

Comparison of water-assisted and gas-assisted injection molding

May 19, 2022Comparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid...view

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

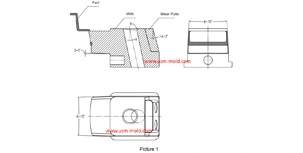

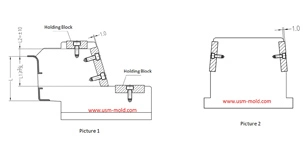

The design requirements of slider wear plate

Jan 2, 20241. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...view

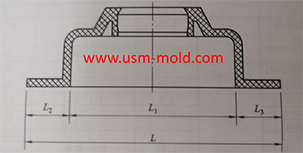

Plastic molding shrinkage rate

Dec 30, 2021Plastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are...view

English

English русский

русский