Dongguan International Machine Tool Exhibition Of 2021 Hedling Successfully

2021 is an extraordinary year, although the epidemic has not completely subsided, it cannot stop the enthusiastic pursuit of new equipment and new technologies in the Chinese manufacturing industry, Dongguan International Machine Tool Show (DME) was held successfully in Guangdong Modern International Exhibition Center on 10th Dec to 13th Dec 2021.

Unique Solutions Solutions Mold Limited (USM) as a member of the machinery mold industry, is lucky to participate in the exhibition in order to know more about the advanced molds and automation technology and keep up with the industry trends, we will bring you the latest frontier reports on the exhibition as following.

Dongguan International Machine Tool Exhibition (DME) conforms to the general development trend of China's manufacturing industry, relying on the superior foundation of Dongguan's manufacturing industry and industrial exhibitions, and is specially approved and hosted by the Foreign Trade Development Bureau of the Ministry of Commerce. To build a bridge for technical exchanges and business cooperation for the development of South China and China's manufacturing industry, 6 main exhibition areas, 130,000 square meters of full-scale opening, nearly 1,700 well-known exhibitors compete on the same field, to build a global advanced medical molding & manufacturing industry a business platform integrating equipment exhibition, machine procurement, technical exchange and manufacturing experience.

Dongguan International Machine Tool Exhibition (DME) is one of the China Machinery chain industry machine tool shows, relying on the layout of the chain industry, it can realize resource cost-sharing and improve the efficiency of exhibition organization, the exhibition organizer can subsidize exhibitors with the saved expenses and reduce their participation costs.

South China is the developed area of our country’s manufacturing industry, Dongguan is also a famous manufacturing centre in China with global influence, it is China’s most competitive exhibition city, the organization and development of machinery exhibitions also have a long history, Houjie Town town of Dongguan already has the market foundation for holding large-scale national machinery exhibitions, the mission of DME at Dongguan International Machine Tool Show is to use efficiency to help customers achieve maximum economic benefits and promote China's economic development.

The exhibition is divided into six main exhibition areas:

1. Hall 1 is the exhibition area for metal cutting machine tools and machine tool accessories;

2. Hall 2 is the exhibition area for grinding tools and measuring tools;

3. Hall 3 is the exhibition area for metal cutting machine tools and accessories;

4. Hall 4A is the exhibition area for metal forming machine tools;

5. Hall 4B, 5, and 6 are smart factory and automation exhibition areas;

7. Hall 7 is the die-casting exhibition area.

The exhibition also invited top experts and scholars in our industry to give academic speeches, the speeches revolved around 4 major topics:

1. SMT International machinery and advanced intelligent seminar: discussion on the intelligent development of CNC equipment for Industry 4.0 by Professor Liuqun Fan from Tongji University, and the key technology of CNC machine research and development explained by Professor Haolin Li from the University of Shanghai for Science and Technology, the CNC energy-saving machining methods and industrial cases shared by Professor Weidong Li of the University of Shanghai for Science and Technology, and the upgrade intelligent practice of CNC machine shared by the CEO Chen Jihong of Wuhan Huazhong numeral control Co. Ltd;

2. The theme of the CNC Intelligent Manufacturing Forum is the dynamic characteristic measurement technology of the machine tool and its application, the basis of 3D digitization-3D digital design and collaborative sharing, the development trend and practical exploration of industrial software, and the exchange of CNC intelligent equipment companies, four major speech sharing composition on new opportunities for road overtaking;

3. The application and innovation of SMC pneumatic technology in the machine tool industry are shared by Shi Zhen from SMC automation Co., Ltd.;

4. The practice and thinking of the transformation and upgrading of the manufacturing industry, the crystallinity of the polymer brought by Zhuozhi Li, Shiqiang Li, Huawei Feng, Canwei Mo and other professionals respectively guides the technological development of the moulding industry, accompanied by the full value chain of FANUC and manufacturing in Dongguan Industry industry insights, the practice and thinking of digital transformation of manufacturing companies, and the mold industry Internet to help the industry's digital upgrade composition.

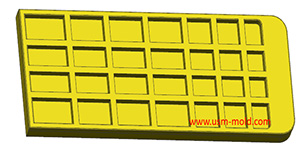

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

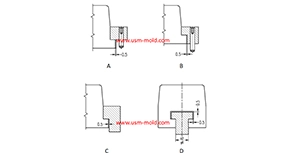

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

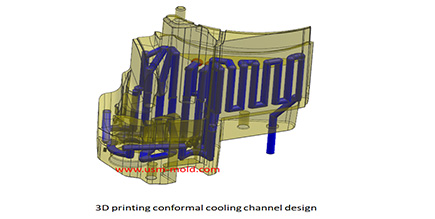

Different treatment of plastic injection mold cooling system principles

Feb 22, 2022Different treatment principle: 1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be...view

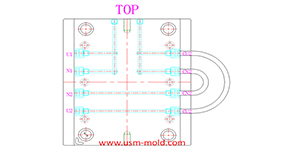

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

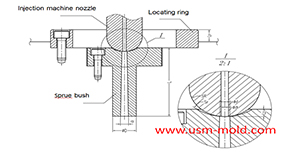

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

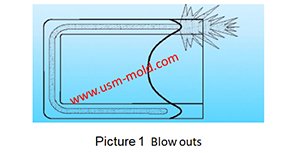

Gas-assisted injection molding product defects and solutions

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

English

English русский

русский

_20250310164515A048.webp)