Different treatment of plastic injection mold cooling system principles

Different treatment principle:

1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be heated.

2. The temperature of the cavity should be higher than the temperature of the core, and the temperature difference is generally 20~30℃.

3. For texture cavity with EDM markson the surface, the cavity temperature should be higher than the general polishing surface, when the cavity must be filled with hot water or hot oil, the general temperature difference is about 40 ℃.

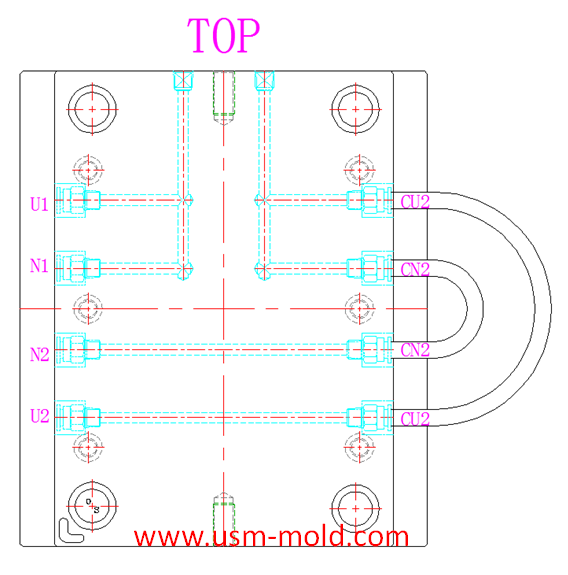

4. For plastic parts with dense meshes, such as speaker shell, the material flow resistance in the mesh area is relatively big and it is difficult to fill. Increasing the mold temperature in this area can improve the filling conditions, the cooling channel in the mesh area is required to be separated from the cooling channel in other areas to flexibly adjust the mold temperature.

5. The mold temperature also depends on the surface quality of the plastic part and the structure of the mold, when designing the temperature control system, it should be targeted from the perspective of the wall thickness of the plastic part, the thick wall should be cooled to prevent shrinkage and deformation; Considering the complexity, cooling should be strengthened at the place where the cavity height fluctuates greatly; the heat of the gate inserts should be strengthened; the cooling channel should be avoided as far as possible through the location of the weld line and the location of the thin wall to prevent the defect more obvious.

6. When the mold temperature is required to be high, such as 70°C or higher, the temperature control of the mold should pay attention to the following:

a. The choice of mold material requires high wear resistance and hardness, heat treatment must be carried out, and the machinability before heat treatment is good.

b. The sealing ring in the mold cooling system should be made of heat-resistant material which is to add the lead.

c. It needs to be a cooling channel between the sliding parts of the mold (such as guide pillar, guide sleeves, etc.) to prevent thermal expansion and contraction from causing movement of moving parts to lock.

d. The shutting-off part of the mold will also strain the shutting-off surface due to thermal expansion and contraction, the shutting-off angle can be appropriately increased to reduce the shutting area, the peripheral interface is formed by inserting.

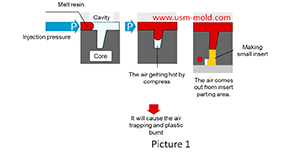

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

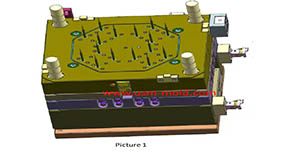

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

What is Ejection Molding?

Dec 28, 2021The process to get injection molded products is called injection molding, or called injection. Injection molding is an important method in polymer molding processing, it is characterized by a short...view

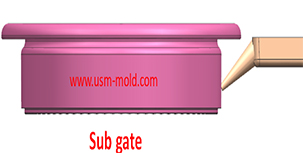

The sub gate of the plastic injection mold runner system

Jan 26, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

The common fixing method of angle pin

May 10, 2024The angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...view

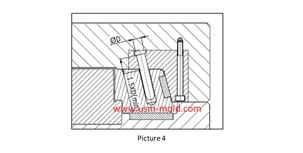

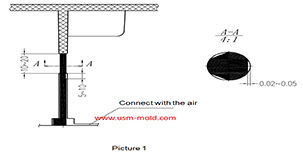

Insert pin of vengting design for molded parts

Mar 20, 2022Insert pin of venting: It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end...view

English

English русский

русский

_20250310164515A048.webp)