Video Of Dongguan International Machine Tool Exhibition In 2021

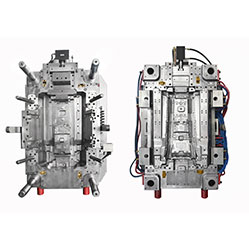

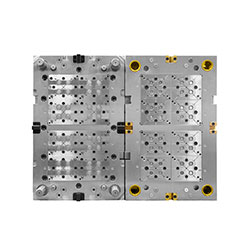

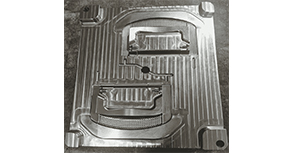

USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mould manufacturing province in China, the plant covers an area of 3500 square meters, and has 85 professional and technical workers who have the ability to manufacture 40 sets of medium-sized plastic molds per month, 85% are exported to European and American countries, we are one of the world's leading manufacturers of plastic injection molding and precision molds.

We serve different industries, especially in the fields of water-assisted mold, gas-assisted mold, two-color mold and pre-deformed mold with professional experience make us standing out in this industry.

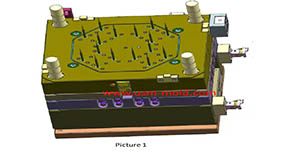

Popular USM Injection Molds

Related News about USM Injection Mold

Side gate of plastic injection mold runner system design

Jan 23, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Limitations of gas-assisted injection molding technology

Apr 25, 2022Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following...view

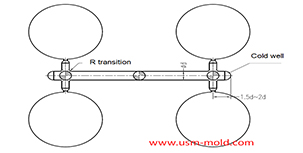

Key points of plastic injection mold runner system

Jan 12, 2022The sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

Slider angle designing tips

Dec 4, 20231. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...view

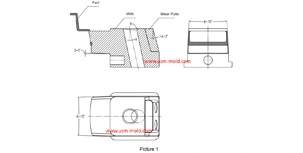

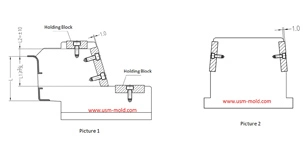

The design requirements of slider wear plate

Jan 2, 20241. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...view

English

English русский

русский