Automotive handle mold

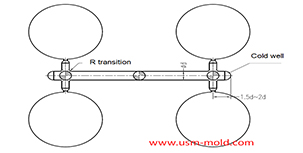

Parting surface venting of runner systemThere are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting s...More+

Parting surface venting of runner systemThere are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting s...More+

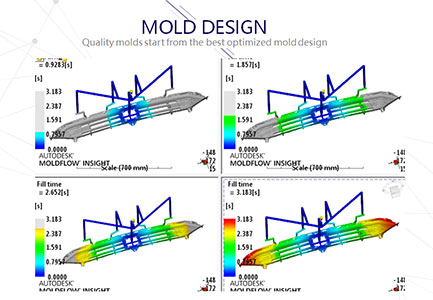

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Water Assisted Injection MouldBecause the flow rate of the outer layer of the melt is slow and the speed of the inner layer is fast, the inner layer of melt will roll outwards and stick to the mold cavity while advancing.More+

Water Assisted Injection MouldBecause the flow rate of the outer layer of the melt is slow and the speed of the inner layer is fast, the inner layer of melt will roll outwards and stick to the mold cavity while advancing.More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

Plastic injection mold heatingWhen the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplast...More+

Plastic injection mold heatingWhen the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplast...More+

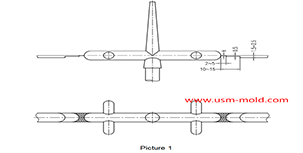

_20250317101412A020.jpg) Main application of gas-assisted molding technologyGas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the m...More+

Main application of gas-assisted molding technologyGas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the m...More+

Automotive MoldAutomotive Molds Characteristics1. The automotive mold size is very big, and the largest mold weight is nearly 40T;2. The mold structure is complex;3. There are many irregular curved surfaces on the parting surface.More+

Automotive MoldAutomotive Molds Characteristics1. The automotive mold size is very big, and the largest mold weight is nearly 40T;2. The mold structure is complex;3. There are many irregular curved surfaces on the parting surface.More+

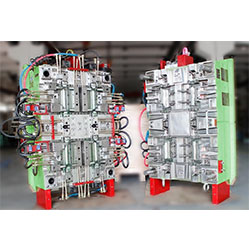

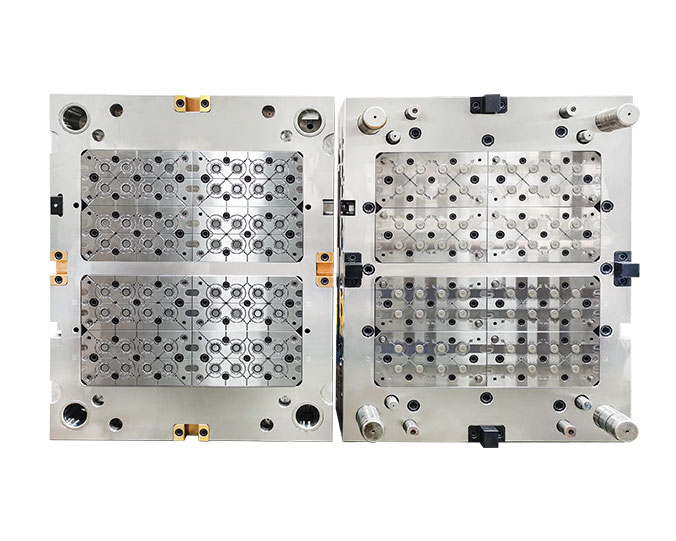

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

English

English русский

русский