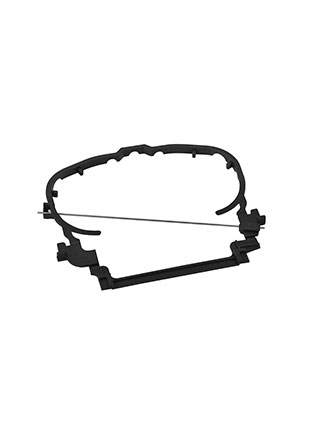

Automotive handle mold

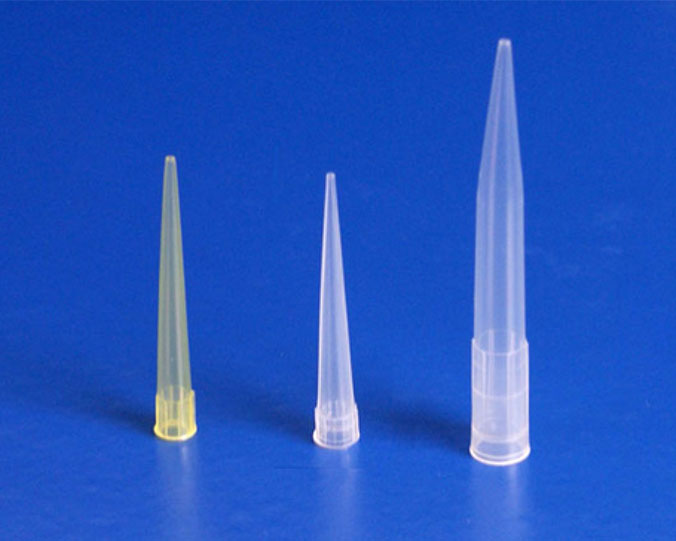

Medical Plastic Injection MoldWhat is the medical injection molded parts?For medical plastic manufacturers, it means that medical supervisors are required to supervise and manage the materials used to manufacture the equipment.More+

Medical Plastic Injection MoldWhat is the medical injection molded parts?For medical plastic manufacturers, it means that medical supervisors are required to supervise and manage the materials used to manufacture the equipment.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

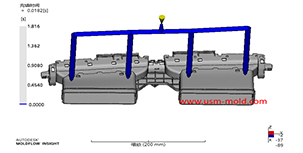

Plastic injection mold runner system design pointsWhen designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically cons...More+

Plastic injection mold runner system design pointsWhen designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically cons...More+

_20250317101412A020.jpg) Main application of gas-assisted molding technologyGas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the m...More+

Main application of gas-assisted molding technologyGas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the m...More+

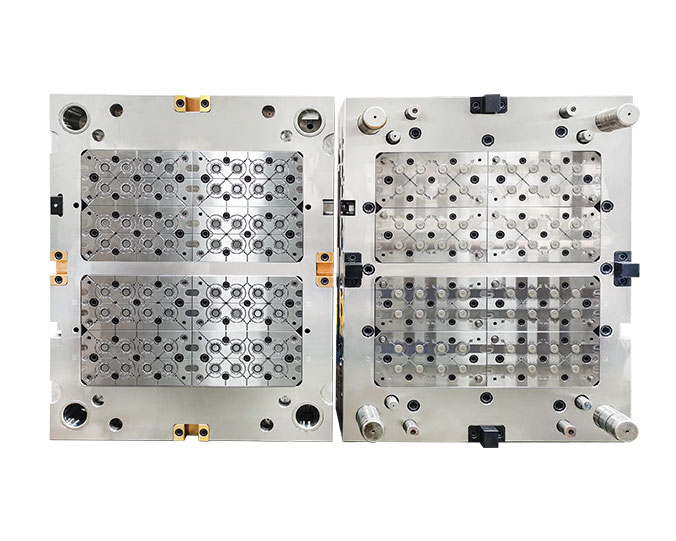

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

English

English русский

русский