gas assisted injection mold factory

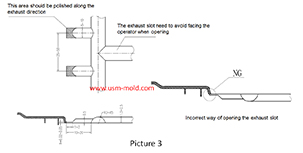

Design standard of exhaust slotThe exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More+

Design standard of exhaust slotThe exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More+

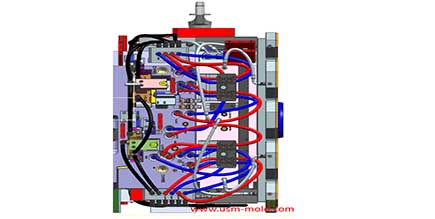

Plastic injection mold cooling system design noticeDesign notice of designing the cooling system:1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer;2. U...More+

Plastic injection mold cooling system design noticeDesign notice of designing the cooling system:1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer;2. U...More+

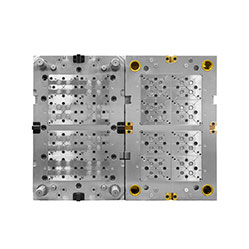

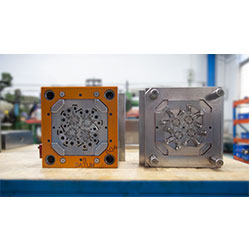

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

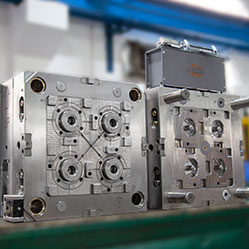

4 Cavity MoldA multi-cavity mold means that multiple identical parts are made in one set mold, and multiple identical parts can be produced in one injection cycle at the same time.More+

4 Cavity MoldA multi-cavity mold means that multiple identical parts are made in one set mold, and multiple identical parts can be produced in one injection cycle at the same time.More+

- Privacy PolicyThis Privacy Policy applies to the worldwide websites of which is part of the Sunkye International. It explains how we collect, process, share, secure and store personal information (information and ...More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

Insert Mold PartsInsert molding is injected with plastic part processing, the insert can be plastic or metal, normally it will be metal parts or thread parts, they must be in a fixed area before injection, so it will be fitting very well after injection finishing. Normally these products request a high standard of strength.More+

Insert Mold PartsInsert molding is injected with plastic part processing, the insert can be plastic or metal, normally it will be metal parts or thread parts, they must be in a fixed area before injection, so it will be fitting very well after injection finishing. Normally these products request a high standard of strength.More+

English

English русский

русский