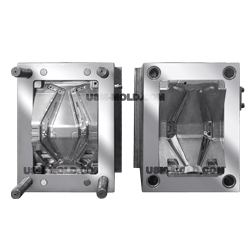

gas assisted injection mold

Plastic injection mold runner system design pointsWhen designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically cons...More+

Plastic injection mold runner system design pointsWhen designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically cons...More+

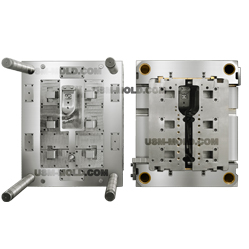

8 Cavity MoldAs a medical plastic injection mold supplier, It has its own unique solutions from medical product development to mold design, mold manufacturing, and injection molding production.More+

8 Cavity MoldAs a medical plastic injection mold supplier, It has its own unique solutions from medical product development to mold design, mold manufacturing, and injection molding production.More+

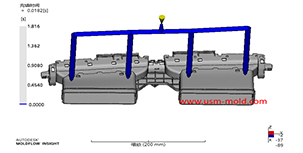

Bike Frame Mold for KidsDuring plastic molding processing, gas-assisted injection molding is abbreviated as GAIM, which is a relatively new molding processing technology, this technology is comprehensively developed on the basis of the design and manufacture of traditional injection molding molds and blow molding molds, and entered the practical stage in the 1990s, gas-assisted injection molding has huge technical application advantages and can produce significant economic benefits.More+

Bike Frame Mold for KidsDuring plastic molding processing, gas-assisted injection molding is abbreviated as GAIM, which is a relatively new molding processing technology, this technology is comprehensively developed on the basis of the design and manufacture of traditional injection molding molds and blow molding molds, and entered the practical stage in the 1990s, gas-assisted injection molding has huge technical application advantages and can produce significant economic benefits.More+

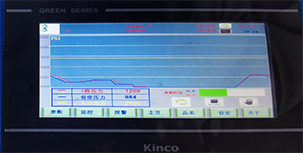

Quality ControlQuality is the soul of USM at all times, the procedure of quality control, quality insurance, and quality monitoring are integrated into every operation step, and all operations are guaranteed with ISO 90001.More+

Quality ControlQuality is the soul of USM at all times, the procedure of quality control, quality insurance, and quality monitoring are integrated into every operation step, and all operations are guaranteed with ISO 90001.More+

The air trapping position in cavity and exhaust methodThe air trapping in cavity is usually in the following places:1. Thin-wall structure cavity, the end of melt flow;2. The junction of two or more melts;3. The last area where the melt in the cavity rea...More+

The air trapping position in cavity and exhaust methodThe air trapping in cavity is usually in the following places:1. Thin-wall structure cavity, the end of melt flow;2. The junction of two or more melts;3. The last area where the melt in the cavity rea...More+

TV Frame MoldPushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.More+

TV Frame MoldPushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.More+

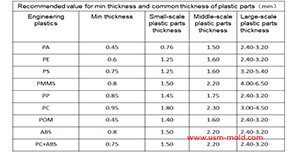

Plastic injection mold heatingWhen the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplast...More+

Plastic injection mold heatingWhen the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplast...More+

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

Banana gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Banana gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

English

English русский

русский