The air trapping position in cavity and exhaust method

The air trapping in cavity is usually in the following places:

1. Thin-wall structure cavity, the end of melt flow;

2. The junction of two or more melts;

3. The last area where the melt in the cavity reaches;

4. The bottom of the blind hole of the mold cavity is mostly the end of a solid column in the part;

5. Reinforcing ribs of molded parts and the bottom of screw pillars;

6. Dead corners of complex mold cavities.

.png)

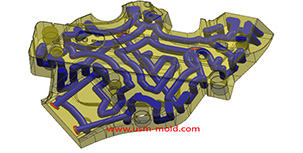

Exhaust method in injection mold include as following:

1. Parting surface (including venting slot);

2. The fitting surface of insert;

3. The fitting surface of the push rod or pipe with inner mold insert;

4. Exhaust from side core pulling mechanism;

5. Add a vent needle or insert to vent the air in the trapped area;

6. Breathable steel exhaust;

7. Air valve exhaust;

8. The mold is evacuated and exhausted.

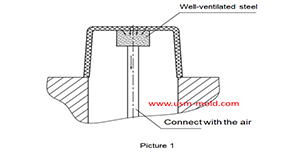

Well-ventilated steel of venting design for molded parts

Mar 14, 2022Well-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow the...view

Plastic cooling factors by injection parameter

Feb 10, 20221. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately...view

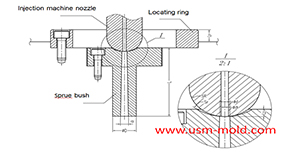

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

Plastic injection mold heating

Feb 16, 2022When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition,...view

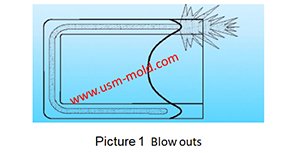

Gas-assisted injection molding product defects and solutions

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

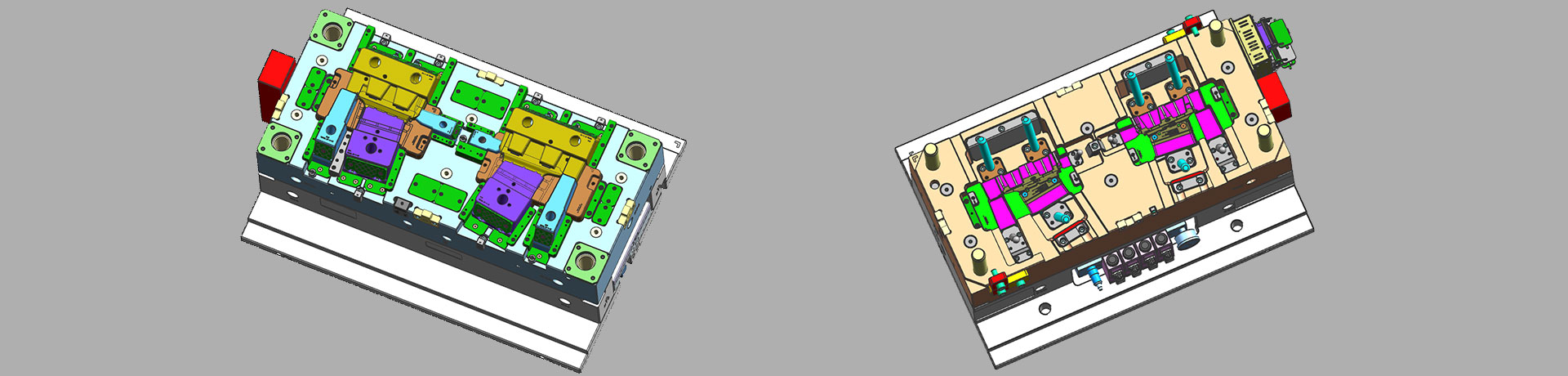

Design principles for wall thickness of plastic products

Jan 3, 2022The principles of wall thickness design for plastic parts are as follows: 1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking...view

English

English русский

русский

_20250310164515A048.webp)