gas assisted injection mold

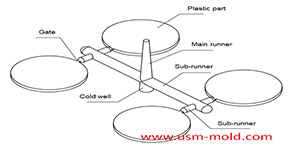

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

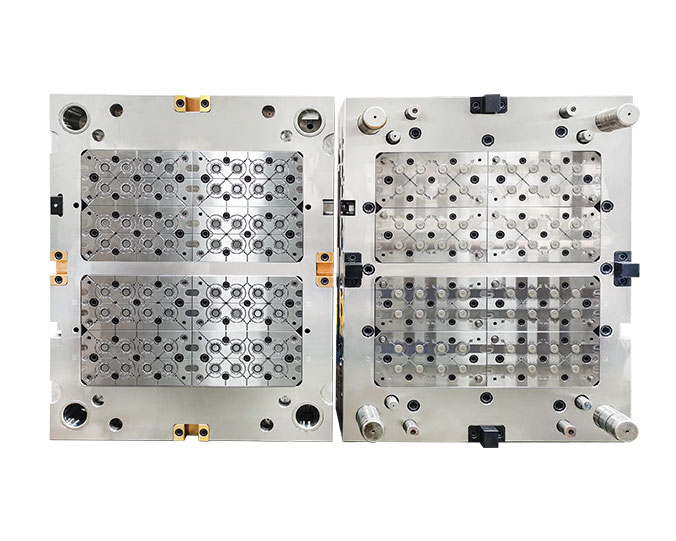

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

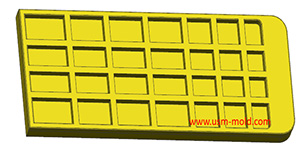

Plastic part ribs desiginingThe ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of t...More+

Plastic part ribs desiginingThe ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of t...More+

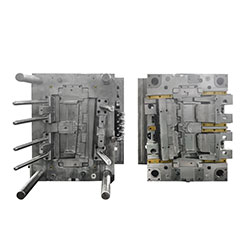

Automotive AC Air OutletThe air outlets of automotive AC are generally assembled by multiple parts, classified according to their functions and purposes: there are exterior molds, functional molds, or both exterior and functional molds.More+

Automotive AC Air OutletThe air outlets of automotive AC are generally assembled by multiple parts, classified according to their functions and purposes: there are exterior molds, functional molds, or both exterior and functional molds.More+

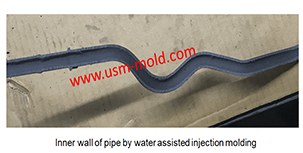

Comparison of water-assisted and gas-assisted injection moldingComparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid an...More+

Comparison of water-assisted and gas-assisted injection moldingComparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid an...More+

Drip Tip MoldThe two-color molding will be made in one same injection machine at the same time by 2 times injection, with 2 injection barrels and 2 different injection gates by 2 different molds, but the product will be picked up one time, it will request 2 molds in one specific 2k injection machine to finish final injection.More+

Drip Tip MoldThe two-color molding will be made in one same injection machine at the same time by 2 times injection, with 2 injection barrels and 2 different injection gates by 2 different molds, but the product will be picked up one time, it will request 2 molds in one specific 2k injection machine to finish final injection.More+

English

English русский

русский