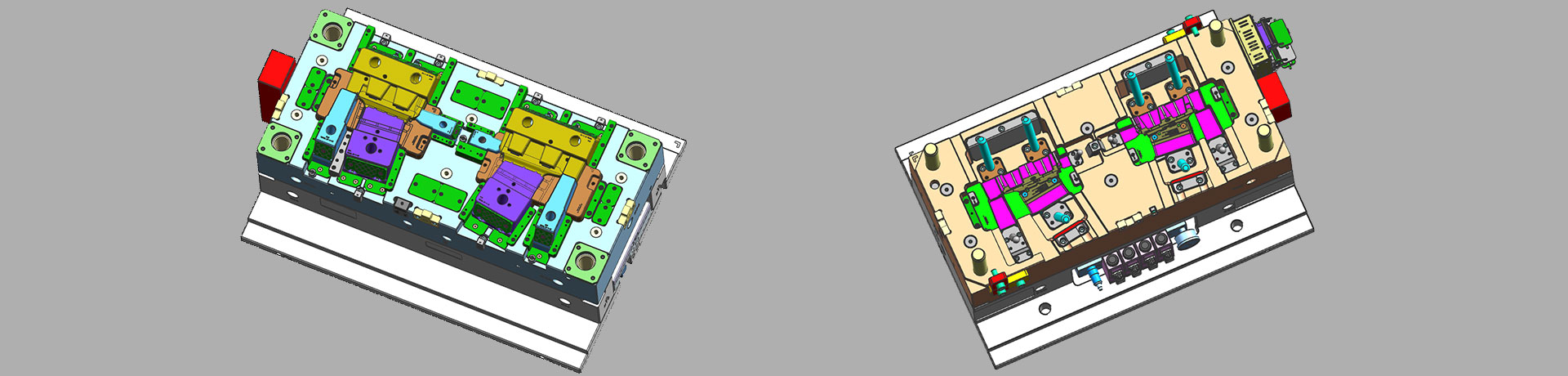

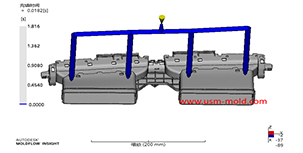

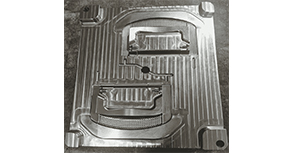

Plastic injection mold runner system design

The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate directly. The function of the gate is make the molten plastic coming from the runner enter and fill the cavity with core by fast speed, after the cavity with core are filled with plastic, the gate can be cooled quickly and sealed to prevent the hot material in the cavity from flowing material.

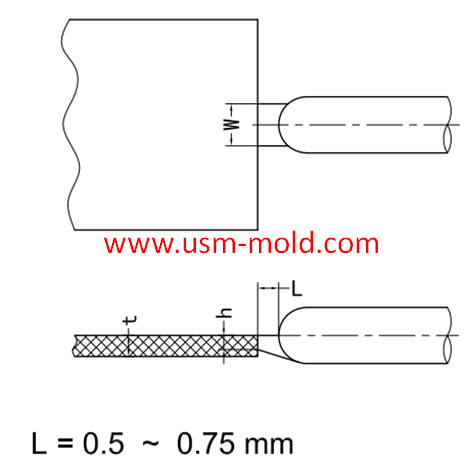

The gate design is related to factors such as the part shape, the cross-sectional size of the part, the plastic performance, the mold structure and the injection process parameters. The gate cross-sectio should be small and the length should be short, so as to increase the material flow speed, fast cooling and sealing to separate the plastic parts, and the gate marks are not obvious.

The gate is a key part of the gating system, the gate location, type and size have a big influence on the plastic parts quality, the quality defects of plastic parts, such as air trapping, shrinkage, water trapping, decomposition, washout, deformation, etc., are often caused by unreasonable gate design. The gate is the smallest part of the entire gating system (except for the direct gate of the sprue type) in many cases.

The design content of the gate includes the following 3 points:

①Select the gate location

②Determine the gate type

③Determine the gate size

We will talk about how to determine the location of the gate in following article.

The air trapping position in cavity and exhaust method

Mar 2, 2022The air trapping in cavity is usually in the following places: 1. Thin-wall structure cavity, the end of melt flow; 2. The junction of two or more melts; 3. The last area where the melt in the cavity...view

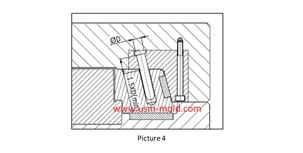

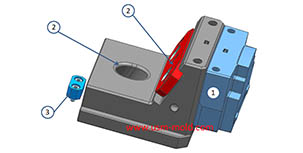

The common fixing method of angle pin

May 10, 2024The angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...view

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view

Limitations of gas-assisted injection molding technology

Apr 25, 2022Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following...view

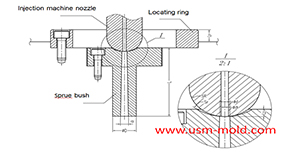

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

Slider designing tips 1

Aug 3, 20221. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially...view

English

English русский

русский