Vacuum venting mold design for plastic molded parts

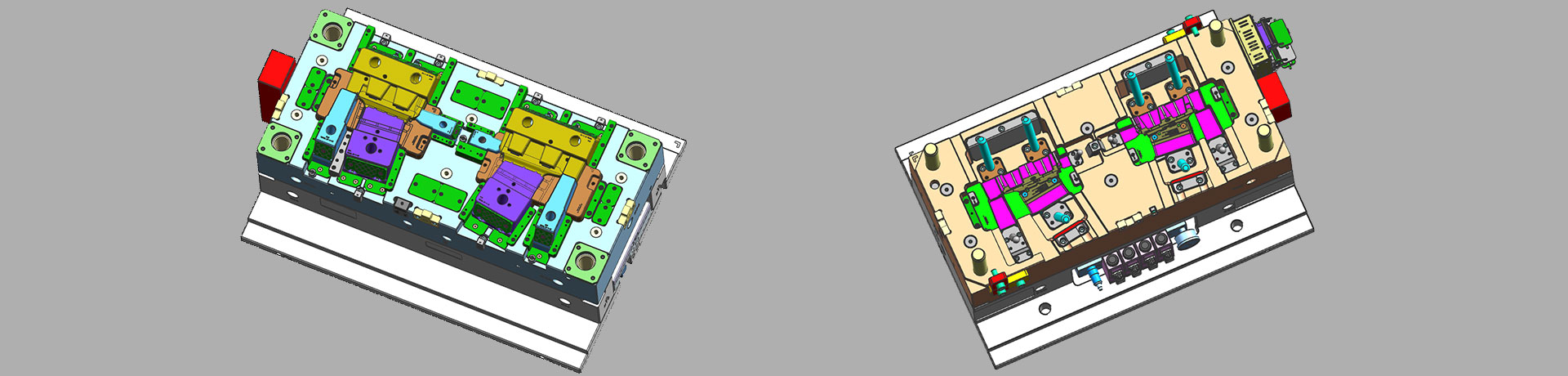

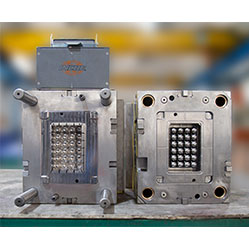

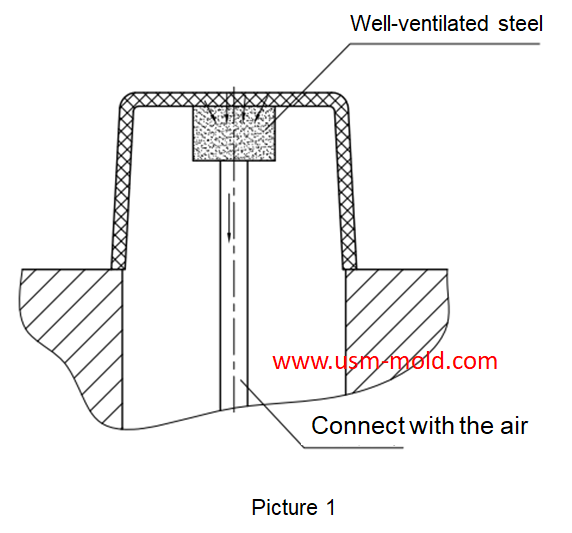

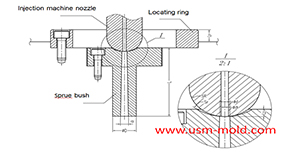

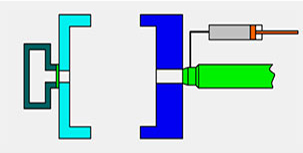

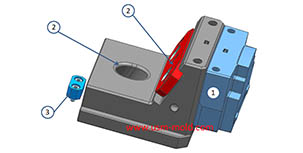

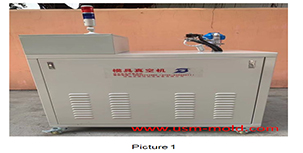

There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm machine and radiotube, the mold design and manufacturing way will be different comparing with the regular mold;

Vacuum injection molding can reduce the injection pressure, and the low injection pressure can ensure a small residual stress of injection molding, and make less part deformation and warpage. After vacuuming, the cavity is in a vacuum state, with the filling of the melt, there is no other gas source except that the melt itself decomposes and may generate gas, controlling the material temperature and filling speed can improve air trapping issue.

The vacuum mold has the following advantages:

1. Improve the filling effect of the product, eliminate the influence of air on the molding, and fundamentally solve the poor venting issue;

2. The vacuum cavity of the mold is easy to fill, reducing the injection pressure and the back pressure of the injection molding machine;

3. Increasing the injection speed, reduce the molding cycle and improve the production efficiency;

4. Improve the welding line of the product and quality;

5. Eliminate the product defects, burning and bubbles.

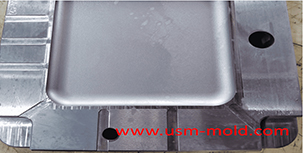

For the precision, thin-walled, large flat parts or complex plastic parts, we should eliminate the air effects for injection, otherwise the part quality is unstable, unfull filling, the big injection pressure will cause the deformation and poor surface.

When making vacumm injection molding is used, the surface of the plastic part is smoother and the molding quality is better. Therefore, the application prospect of vacuum injection mold is very common. For example, the smart phones requires products with thin walls, and some parts add glass fiber to increase strength. Generally, what cannot be achieved by conventional injection molding equipment and processes must be produced by high-speed injection molding machines, and the injection molding process must also be adjusted accordingly, and high-speed and high-pressure injection must be used. This brings a great challenge to the exhaust of the mold in a short time. So many molds must be supplemented by vacuuming to complete. Injection molding is a complex process, and many factors must be considered in order to produce high-quality, stylish and high qualiy products.

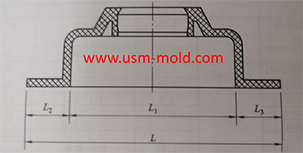

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

Plastic molding shrinkage rate

Dec 30, 2021Plastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are...view

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

Venting system of plastic injection mold introduction

Feb 27, 2022Hello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the...view

Slider designing tips 1

Aug 3, 20221. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially...view

Vacuum venting mold design for plastic molded parts

Mar 23, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

English

English русский

русский