What is Plastic Injection Mold?

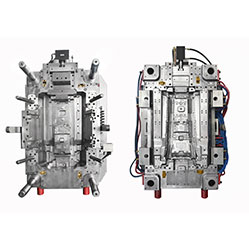

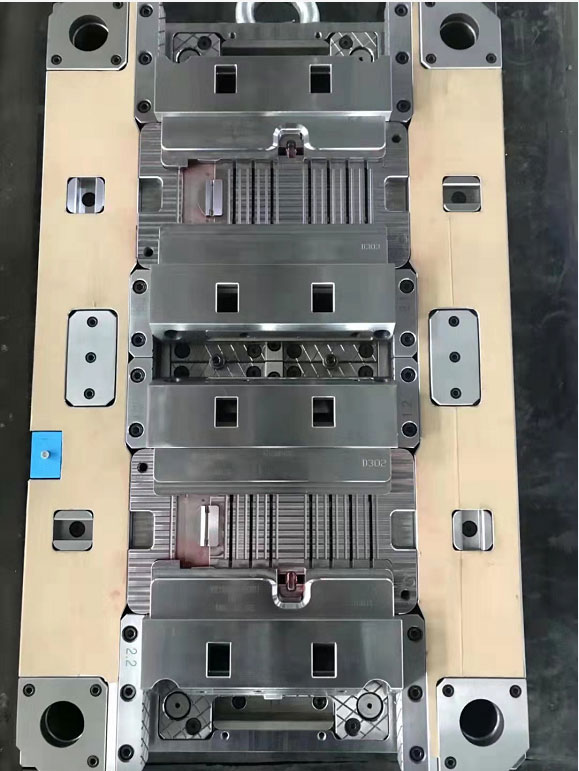

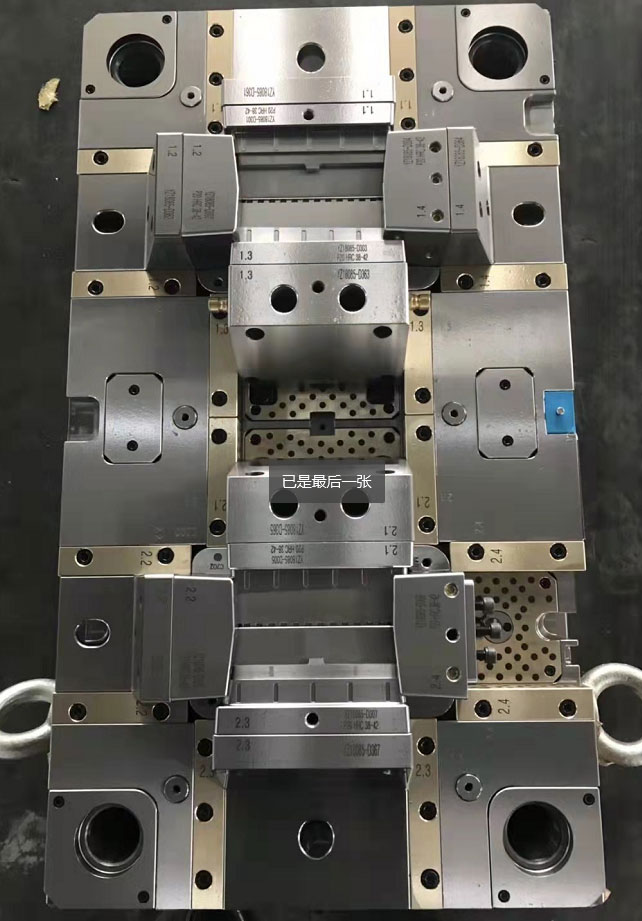

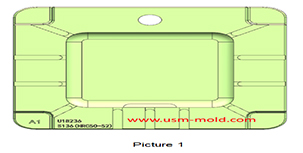

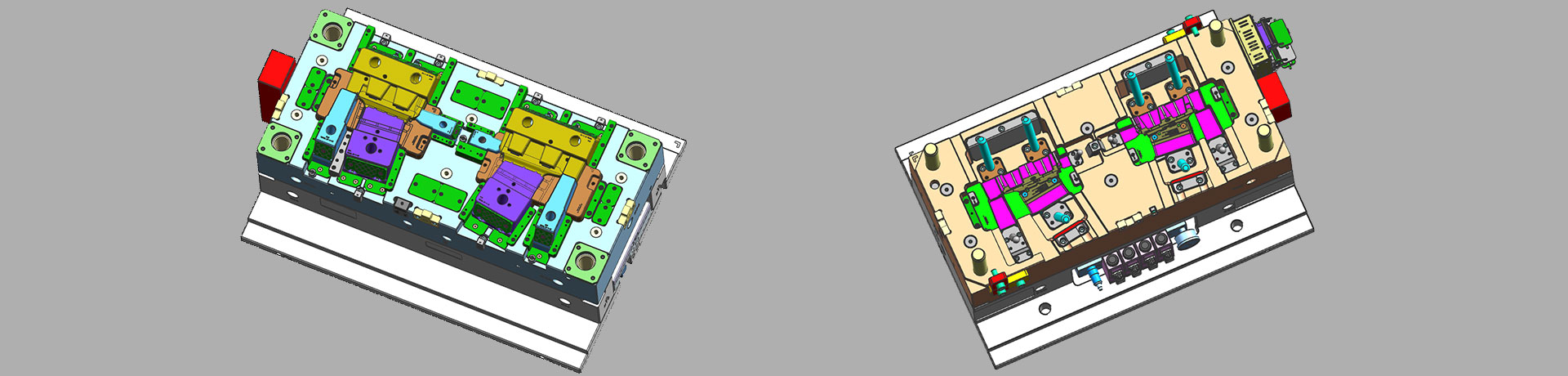

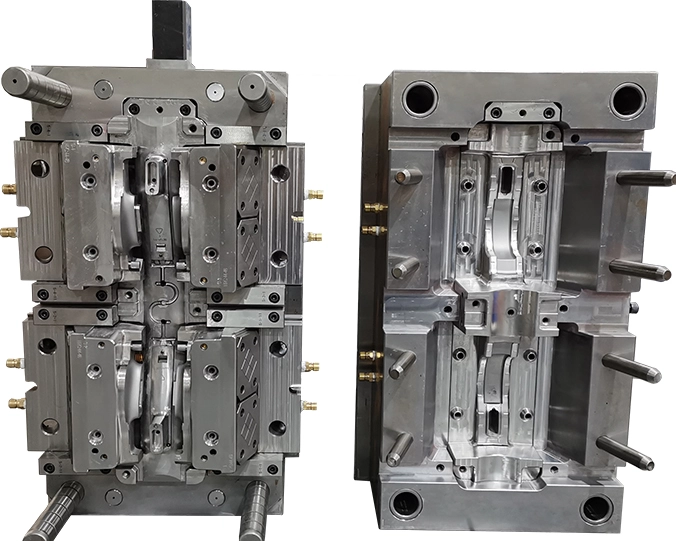

The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and sizes.

The meaning of plastic injection mold:

1. It is suitable for mass production, the mould life is normally in 500-1000K shots, so injection mold is suitable to produce high volume products;

2. The product quality is stable since the mass production mold is made of hardened steel, so the product size and shape are very precise, with suitable injection machines and moulding parameters and production management, the product dimensions will be the same all the time.

3. The molding cycle is short and the production efficiency is very quick, the fastest injection cycle can be achieved within 3 seconds, only the plastic injection mold can meet the production demand if the volume of the products is very large;

4. It has a wide range of adaptability, the mold steel can be chosen according to the different product quantities in order to save mold cost like we normally use 1.1730 and S50C for prototype molds, and the mold life can be reached to 10k shots. But for other large quantities, we will use 1.2343, 1.2344, 1.2738, 718, 718H, 738, 738H, S136, S136H, SKD61,8407, NAK80 and H13 to make different plastic material parts.

5. It is suitable for automatic production to reduce labour costs and unstable factors.

Injection mold classification:

There are many ways to classify plastic injection mold, according to the plastic material which can be divided into thermoplastic and thermosetting injection molding, we will talk about thermoplastic injection molds as below, and the injection machine can be divided into horizontal injection molding machines and injection molding for vertical injection molding machines, and Greek injection molding machines, etc.

The injection machine can be divided into the following according to different structures:

1. Single parting surface injection mold: it is also called two-plate injection mold which is the simplest injection mold;

2. Double parting surface injection mold: it is also called three-plate injection mold, it has 2 parting surfaces, one parting surface used for picking up the part, the other one used for gating system;

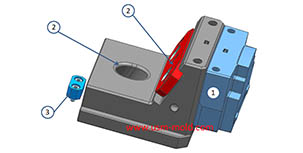

3. With lateral parting screwing injection mold: when the part side contains holes convex or concave structural features, the mold will need to design the side un-screwing (or crosswise) to pick up the plastic part;

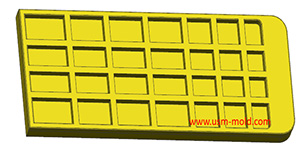

4. Multi-layer injection mold: The mold contains two or more layers of cavities which will be overlapping manner, this type of mold is suitable for small parts, it can increase 80% output comparing the normal mold, but the injection machine requires a larger mold opening stroke, it is also called stack mold;

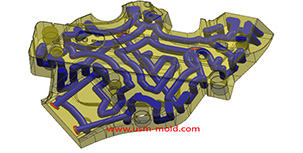

5. Zero runner injection mold: zero runner injection mold is also called hot runner injection mold, the plastic material will always keep in liquid in the runner by heating so that the pressure is transmitted well and there is no cold runner left after demolding, it can save plastic raw materials and improve production efficiency and product quality.

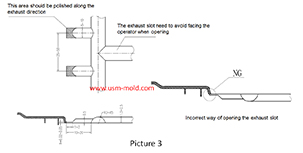

Design standard of exhaust slot

Mar 3, 2022The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...view

Venting of parting surface

Mar 7, 2022The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...view

Plastic cooling factors by injection parameter

Feb 10, 20221. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately...view

Slider designing tips 1

Aug 3, 20221. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially...view

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

Unique Solutions Mold Profile

Dec 27, 2021USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square...view

English

English русский

русский

_20250310164515A048.webp)