Automotive handle injection molding

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

- Leading manufacturers of plastic injection mould and molded parts.We have always pushed developments forward and set benchmarks in Automtive, High precision and 2K molding and other industrial parts.More+

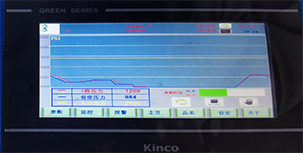

Gas-assisted Injection Molding EquipmentThe gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection ...More+

Gas-assisted Injection Molding EquipmentThe gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection ...More+

Key points of gas-assisted injection molding processGas injection parametersThe gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas i...More+

Key points of gas-assisted injection molding processGas injection parametersThe gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas i...More+

English

English русский

русский