Automotive handle injection molding

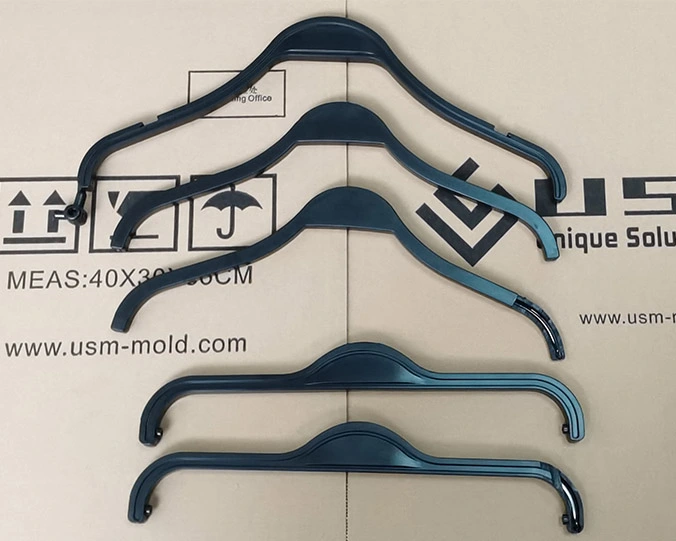

Gas-Assisted Injection Molding in Plastic HangersGas-assisted molding is a plastic injection molding technology that injects gas into the plastic in a molten state, forming a cavity inside the plastic, thereby achieving the purpose of reducing weigh...More+

Gas-Assisted Injection Molding in Plastic HangersGas-assisted molding is a plastic injection molding technology that injects gas into the plastic in a molten state, forming a cavity inside the plastic, thereby achieving the purpose of reducing weigh...More+

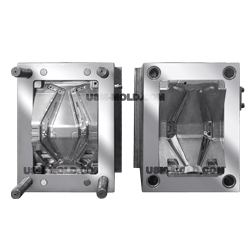

TV Frame MoldPushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.More+

TV Frame MoldPushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.More+

Car Door MoldThe product is an assembly functional part with very high requirements for size and installation location, and it is an external part, there are very strict requirements on the clearance and tolerance after installation;More+

Car Door MoldThe product is an assembly functional part with very high requirements for size and installation location, and it is an external part, there are very strict requirements on the clearance and tolerance after installation;More+

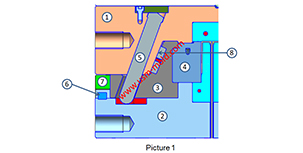

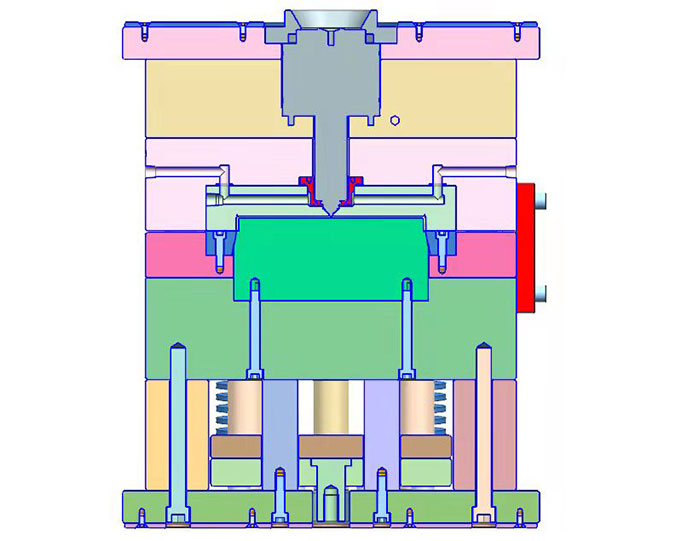

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

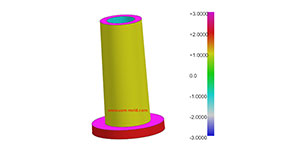

What is Called Draft Angle?The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in pictureMore+

What is Called Draft Angle?The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in pictureMore+

Cold Runner & Hot Runner Plastic MoldCommon Hot Runner Temperature Sensing Wires Types And CharacteristicsGenerally, the temperature-sensitive wire is composed of steel wire insulated with a heat-sensitive material, the temperature sensig wire is commonly known as the "thermocouple".More+

Cold Runner & Hot Runner Plastic MoldCommon Hot Runner Temperature Sensing Wires Types And CharacteristicsGenerally, the temperature-sensitive wire is composed of steel wire insulated with a heat-sensitive material, the temperature sensig wire is commonly known as the "thermocouple".More+

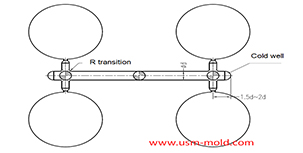

Key points of plastic injection mold runner systemThe sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...More+

Key points of plastic injection mold runner systemThe sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...More+

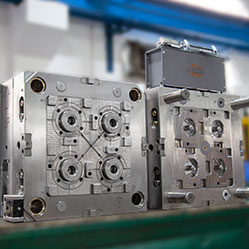

4 Cavity MoldA multi-cavity mold means that multiple identical parts are made in one set mold, and multiple identical parts can be produced in one injection cycle at the same time.More+

4 Cavity MoldA multi-cavity mold means that multiple identical parts are made in one set mold, and multiple identical parts can be produced in one injection cycle at the same time.More+

2022 Shenzhen Industrial Exhibition ITES ended successfullyThe 2022 ITES Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition and the 23rd Shenzhen International Machinery Manufacturing Exhibition were grandly opened in Shenzhen...More+

2022 Shenzhen Industrial Exhibition ITES ended successfullyThe 2022 ITES Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition and the 23rd Shenzhen International Machinery Manufacturing Exhibition were grandly opened in Shenzhen...More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

English

English русский

русский