Automotive handle injection molding

Five Major Steps of the Injection Mold Production ProcessInjection mold manufacturing can be roughly divided into the following steps:Process analysis of plastic products.More+

Five Major Steps of the Injection Mold Production ProcessInjection mold manufacturing can be roughly divided into the following steps:Process analysis of plastic products.More+

Car Ceiling Handle Injection MouldWhen plastic injection molding, the melt is under the injection pressure and enters the mold cavity, on the same section, the flow rate of each gate is different, the fastest in the middle, the closer to the cavity wall, the slower the flow rate, and it contacts the cavity wall, the speed of the first layer is zero.More+

Car Ceiling Handle Injection MouldWhen plastic injection molding, the melt is under the injection pressure and enters the mold cavity, on the same section, the flow rate of each gate is different, the fastest in the middle, the closer to the cavity wall, the slower the flow rate, and it contacts the cavity wall, the speed of the first layer is zero.More+

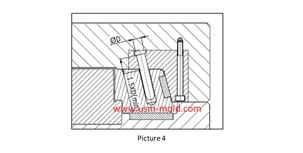

The common fixing method of angle pinThe angle pin is a common part of the drive slider, and the fixing and installation methods as following:1. Pass through the mold plate directly and press the angle pin with the top plate to fix it, a...More+

The common fixing method of angle pinThe angle pin is a common part of the drive slider, and the fixing and installation methods as following:1. Pass through the mold plate directly and press the angle pin with the top plate to fix it, a...More+

Visual Doorbell Housing MoldLighting control can adjust the lighting of all rooms by pressing a few buttons, the scene function can realize various scene modes, and the full turn on and off function can realize the one-key to turn on and off functions of all lamps and lanterns.More+

Visual Doorbell Housing MoldLighting control can adjust the lighting of all rooms by pressing a few buttons, the scene function can realize various scene modes, and the full turn on and off function can realize the one-key to turn on and off functions of all lamps and lanterns.More+

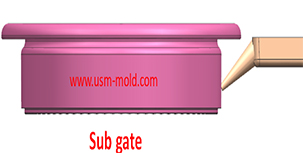

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

PA66 GF30 Car Parts Plastic Injection MoldPre-deformation means that the product will be designed mold in opposite direction in advance. The product is injected and cooled by natural shrinkage, the two deformations will be offset to obtain a product and meet the drafting tolerance.More+

PA66 GF30 Car Parts Plastic Injection MoldPre-deformation means that the product will be designed mold in opposite direction in advance. The product is injected and cooled by natural shrinkage, the two deformations will be offset to obtain a product and meet the drafting tolerance.More+

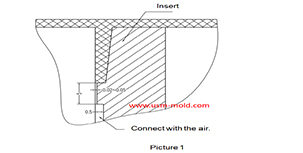

Venting insert design of molded partsIn the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw colu...More+

Venting insert design of molded partsIn the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw colu...More+

Auto Parts MouldThe automotive console is an external part in automotive interior parts, and no weld line on the part surface, the console's gating system generally uses a valve gate of hot runner system, the gate position usually has a direct injection gate on the non-critical surface which is to save plastic material, the shut-off area will be injected on side of the non-critical surface, or the middle area will be injected to the non-critical surface by the banana gate.More+

Auto Parts MouldThe automotive console is an external part in automotive interior parts, and no weld line on the part surface, the console's gating system generally uses a valve gate of hot runner system, the gate position usually has a direct injection gate on the non-critical surface which is to save plastic material, the shut-off area will be injected on side of the non-critical surface, or the middle area will be injected to the non-critical surface by the banana gate.More+

English

English русский

русский