Automotive handle injection molding

PA66 GF30 Car Parts Plastic Injection MoldPre-deformation means that the product will be designed mold in opposite direction in advance. The product is injected and cooled by natural shrinkage, the two deformations will be offset to obtain a product and meet the drafting tolerance.More+

PA66 GF30 Car Parts Plastic Injection MoldPre-deformation means that the product will be designed mold in opposite direction in advance. The product is injected and cooled by natural shrinkage, the two deformations will be offset to obtain a product and meet the drafting tolerance.More+

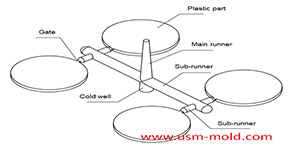

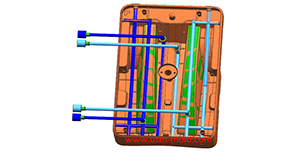

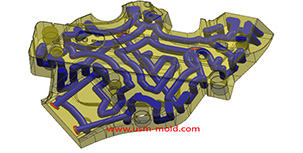

The principle of mold temperature balance in plastic mold cooling system designThe principle of mold temperature balance:1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be mak...More+

The principle of mold temperature balance in plastic mold cooling system designThe principle of mold temperature balance:1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be mak...More+

Car Door MoldThe product is an assembly functional part with very high requirements for size and installation location, and it is an external part, there are very strict requirements on the clearance and tolerance after installation;More+

Car Door MoldThe product is an assembly functional part with very high requirements for size and installation location, and it is an external part, there are very strict requirements on the clearance and tolerance after installation;More+

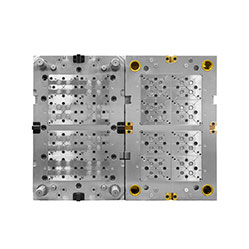

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

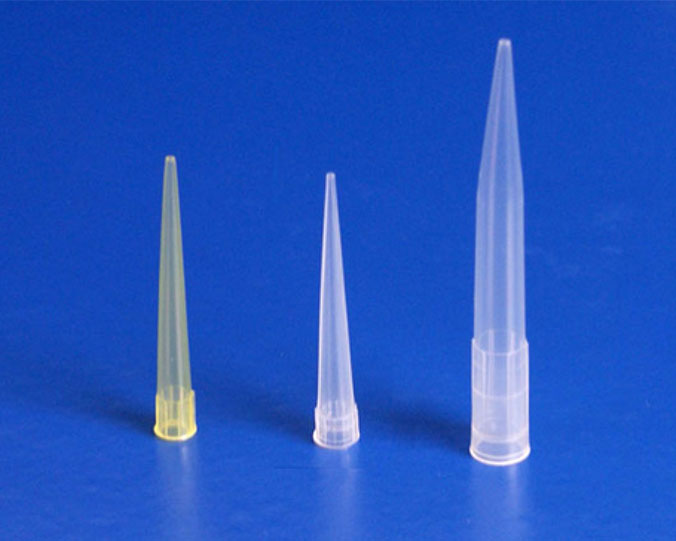

Medical Plastic Injection MoldWhat is the medical injection molded parts?For medical plastic manufacturers, it means that medical supervisors are required to supervise and manage the materials used to manufacture the equipment.More+

Medical Plastic Injection MoldWhat is the medical injection molded parts?For medical plastic manufacturers, it means that medical supervisors are required to supervise and manage the materials used to manufacture the equipment.More+

Water Proof Plastic Enclosure MoldThe product will be made by two times, which will inject the second piece after finishing the first piece in the other mold and different injection machine, normally will be no specific request for 2 different pieces injection time, injection machine.More+

Water Proof Plastic Enclosure MoldThe product will be made by two times, which will inject the second piece after finishing the first piece in the other mold and different injection machine, normally will be no specific request for 2 different pieces injection time, injection machine.More+

Automotive Grille MoldThe part surface of the air intake grille generally has several treatment methods such as leather texture, sandblasting, paint spraying, and electroplating, the materials usually are PP, ABS, ASA, etc., and the surface of the bumper decorative grille is generally treated with leather texture and sandblasting, mainly PP material.More+

Automotive Grille MoldThe part surface of the air intake grille generally has several treatment methods such as leather texture, sandblasting, paint spraying, and electroplating, the materials usually are PP, ABS, ASA, etc., and the surface of the bumper decorative grille is generally treated with leather texture and sandblasting, mainly PP material.More+

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

English

English русский

русский