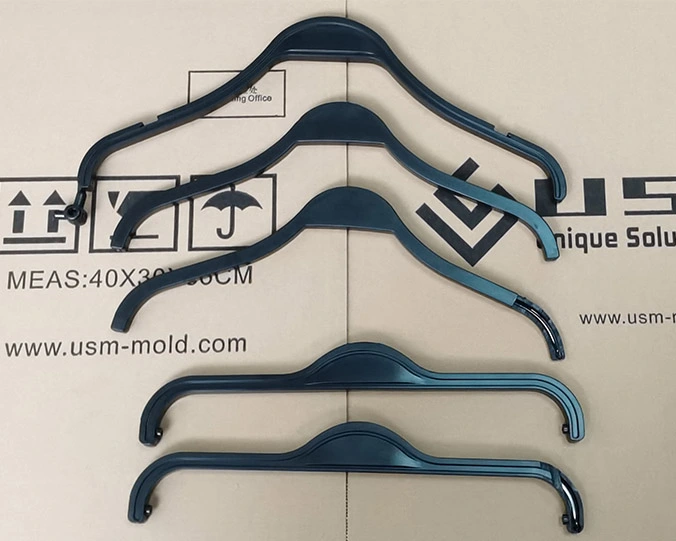

Automotive handle injection molding

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

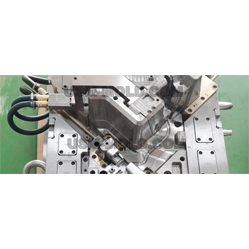

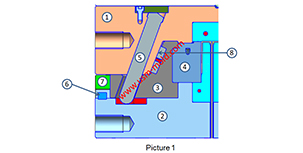

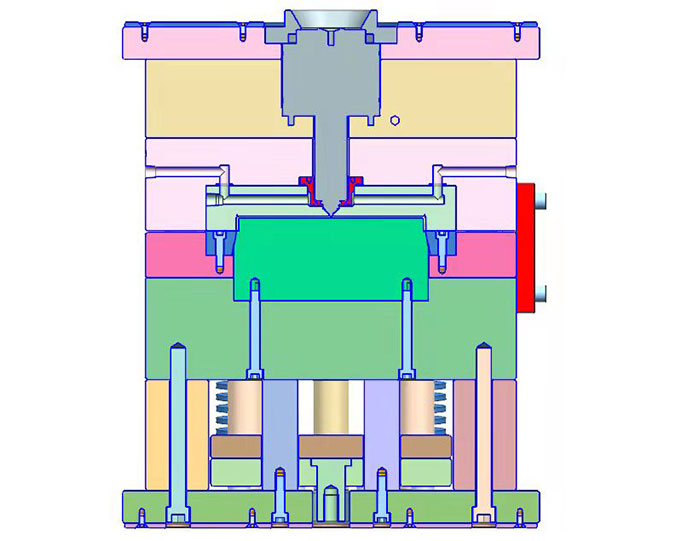

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

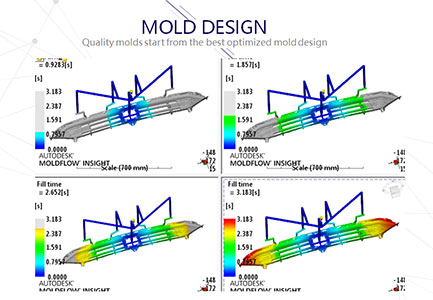

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Cold Runner & Hot Runner Plastic MoldCommon Hot Runner Temperature Sensing Wires Types And CharacteristicsGenerally, the temperature-sensitive wire is composed of steel wire insulated with a heat-sensitive material, the temperature sensig wire is commonly known as the "thermocouple".More+

Cold Runner & Hot Runner Plastic MoldCommon Hot Runner Temperature Sensing Wires Types And CharacteristicsGenerally, the temperature-sensitive wire is composed of steel wire insulated with a heat-sensitive material, the temperature sensig wire is commonly known as the "thermocouple".More+

Pin-point gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Pin-point gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

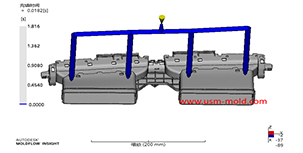

Plastic injection mold runner system design pointsWhen designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically cons...More+

Plastic injection mold runner system design pointsWhen designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically cons...More+

English

English русский

русский