Injection Mold

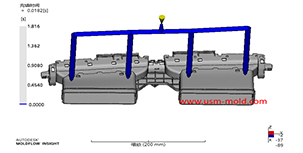

The air trapping position in cavity and exhaust methodThe air trapping in cavity is usually in the following places:1. Thin-wall structure cavity, the end of melt flow;2. The junction of two or more melts;3. The last area where the melt in the cavity rea...More+

The air trapping position in cavity and exhaust methodThe air trapping in cavity is usually in the following places:1. Thin-wall structure cavity, the end of melt flow;2. The junction of two or more melts;3. The last area where the melt in the cavity rea...More+

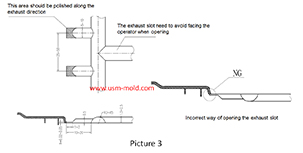

Design standard of exhaust slotThe exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More+

Design standard of exhaust slotThe exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More+

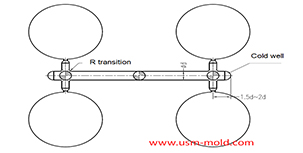

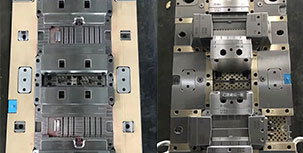

Parting surface venting of runner systemThere are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting s...More+

Parting surface venting of runner systemThere are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting s...More+

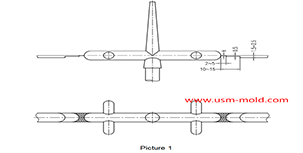

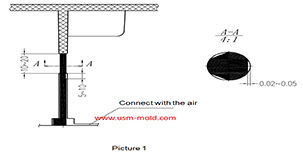

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

USM Blogo OpeningHello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need.More+

USM Blogo OpeningHello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need.More+

Five Major Steps of the Injection Mold Production ProcessInjection mold manufacturing can be roughly divided into the following steps:Process analysis of plastic products.More+

Five Major Steps of the Injection Mold Production ProcessInjection mold manufacturing can be roughly divided into the following steps:Process analysis of plastic products.More+

What is Plastic Injection Mold?The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and sizes.More+

What is Plastic Injection Mold?The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and sizes.More+

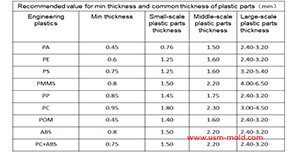

Design principles for wall thickness of plastic productsThe principles of wall thickness design for plastic parts are as follows:1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking eve...More+

Design principles for wall thickness of plastic productsThe principles of wall thickness design for plastic parts are as follows:1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking eve...More+

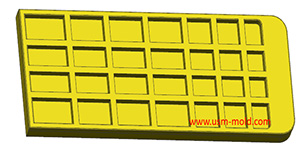

Plastic part ribs desiginingThe ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of t...More+

Plastic part ribs desiginingThe ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of t...More+

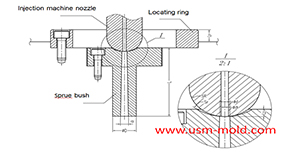

Plastic injection mold runner system design pointsWhen designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically cons...More+

Plastic injection mold runner system design pointsWhen designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically cons...More+

English

English русский

русский