Mold Supplier

The design principle of the exhaust slotThe exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality...More+

The design principle of the exhaust slotThe exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality...More+

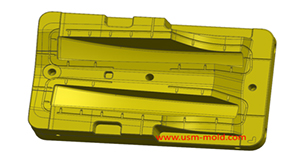

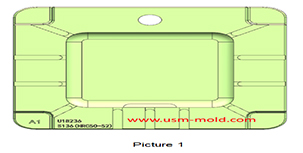

Venting of parting surfaceThe exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...More+

Venting of parting surfaceThe exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...More+

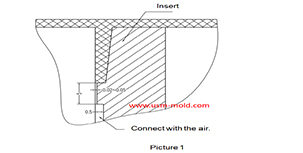

Venting insert design of molded partsIn the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw colu...More+

Venting insert design of molded partsIn the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw colu...More+

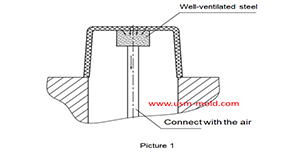

Well-ventilated steel of venting design for molded partsWell-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow th...More+

Well-ventilated steel of venting design for molded partsWell-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow th...More+

Vacuum venting mold design for plastic molded partsThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

Vacuum venting mold design for plastic molded partsThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

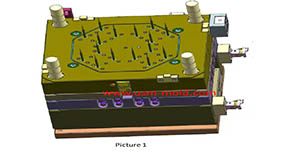

Design Tips of Vacuum Venting MoldThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

Design Tips of Vacuum Venting MoldThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

Gas-assisted Injection Molding EquipmentThe gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection ...More+

Gas-assisted Injection Molding EquipmentThe gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection ...More+

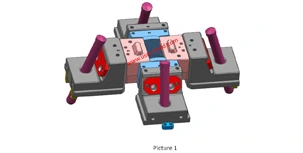

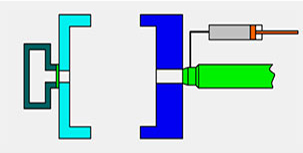

The difference between full shot and short shot of gas-assisted injection moldingGas-assisted injection molding can be divided into short shot and full shot.Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filli...More+

The difference between full shot and short shot of gas-assisted injection moldingGas-assisted injection molding can be divided into short shot and full shot.Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filli...More+

English

English русский

русский

_20250317101606A022.jpg)